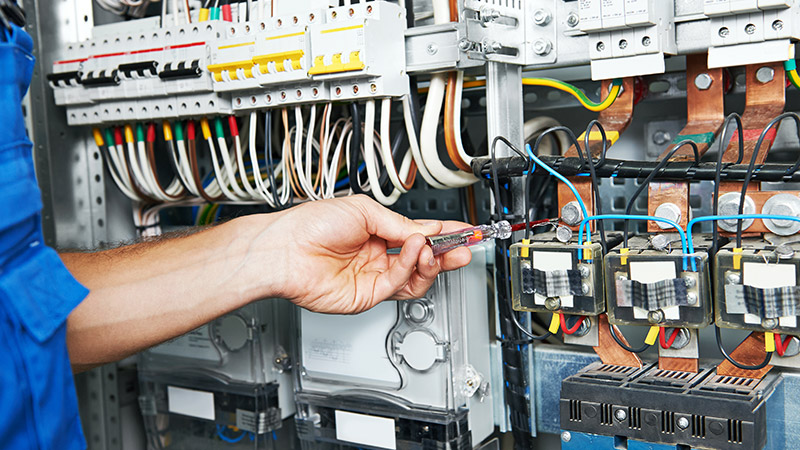

Pelatihan ini memberikan pengetahuan mengenai perawatan dan perbaikan peralatan lestrik dan mekanik yang ada di industry. Pelatihan ditekankan pada system electrical instalation, motor=motor listrik, pompa maupun compressor.setelah mengikuti pelatihan pelatihan diharapkan para peserta dapat :

Pelatihan ini memberikan pengetahuan mengenai perawatan dan perbaikan peralatan lestrik dan mekanik yang ada di industry. Pelatihan ditekankan pada system electrical instalation, motor=motor listrik, pompa maupun compressor.setelah mengikuti pelatihan pelatihan diharapkan para peserta dapat :

* Meahami system instalasi listrik dan hukum dasar kelistrikan

* Memahami Persyaratan Umum Instalasi Tenaga Listrik di Industri

* Menganalisa Diagram Instalasi Tenaga Listrik dan melakukan troubleshooting

* Memahami prinsip kerja, fungsi dan karakteristik peralatan elektrik dan mekanik di Industri

* Memahami tipe dan karakteristik pompa dan kompressor

* Memahami aplikasi dan sizing pompa dan kompressor

* Memahami factor-faktor pemeliharaan peralatan elektrik dan mekanik di industri

MATERI

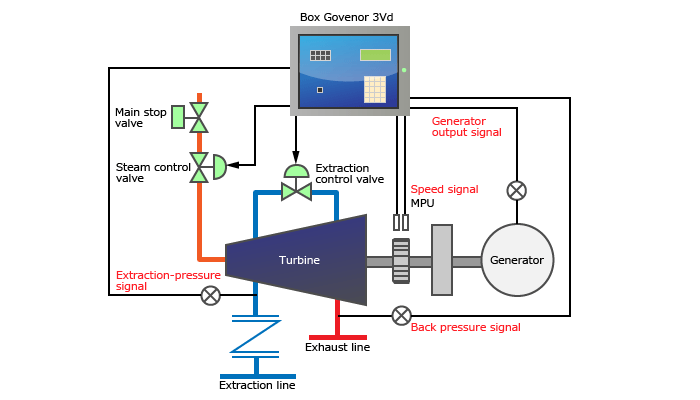

1. Basic Electrical

* Electrical Sources

* Electrical Power Plant Configuration and Equipments

* Electrical Laws

2. Electric Motor Fundamental

* Fundamental Concepts

* DC Motor

* Type of Excitation

* DC Motor Characteristic

3. Three Phase Induction Motor

* Motor Construction

* Armature Winding Techniques

* Princip of Operation

* Motor Characteristic

* Induction Motor Selection

4. Electrical Motor and Installation

* Electrical Power Installation Requirement

* Motor Control Devices

* Motor Control Circuits and Wiring

* Motor Protection

5. Electrical Motor Installation Maintenance and Testing

* Insulation Testing

* Stator and Rotor Testing

6. Pumps

* Types Of Pumps

* Standards and Codes Related To Pump Design

* Main Elements Of Pump Construction

* Selection and Sizing Of Pump

7. Compressors

* Types of Compressors

* Standards and Codes Related to Compressor Design

* Main Elements of Compressor Construction

* Selection and Sizing of Compressor

8. Bearing Techniques

* Types of Bearing

* Bearing Part Numbers

* Shaft and Bearing Housing Fits and Tolerances

* Mounting Methods

* Dismounting Methods

* Bearing Damages

9. Lubrication

* Grease Lubrication

* Base Oil Viscosity

* Temperature Range

* Re-lubrication

* Oil Lubrication

* Mineral Oils

* EP Additives

* Synthetic Oils

10. Maintenance of Equipment

* Type Of Maintenance

* Frequency Of Maintenance

* Measurement and Testing

PARTICIPANTS

Minimum SLTA; untuk para operator, teknisi, engineer, perancang, penyelia, manajer, dan lain-lainnya yang ingin mengetahui/memahami/mendalami pengetahuan dan ketrampilan tentang system elektrik dan mekanik di industri.

METHOD

Presentation

Discussion

Case Study

Evaluation